Development of new separators for NiZn – Phd defense

On December 19th, David Vidal defended brilliantly his PhD thesis about the development and evaluation of new separators for NiZn batteries. David carried his work within the LPPI laboratory in CY Cergy Paris University under the direction of Pr. Odile Fichet, Dr. Linda Chikh and Dr. Séverine Alfonsi.

The work of Dr. Vidal was part of the WP3 of LOLABAT project dedicated to the improvement of various components for increasing the cyclability and decreasing the costs of NiZn batteries. The separator which was specifically studied in this work is a key element in NiZn batteries that controls selectively the diffusion of ionic species towards and away from the electrode. Thus, the separator must present an adequate ionic conductivity to avoid detrimental effects on the battery performance and acts as a physical barrier preventing electrical short circuits upon dendrite growth at the electrode.

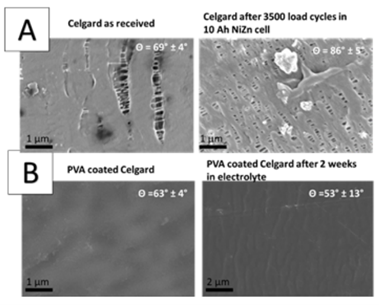

Separators are usually surfactant coated microporous membranes such as commercial Celgard®. David Vidal’s work showed that the coating of commercial separators is physically and chemically deteriorated, almost completely removed, after long term NiZn battery cycling and ex-situ degradation tests developed for the project (see SEM images A). Such degradation of the separator affects the durability of the NiZn cell performances. To overcome this issue, a polypropylene membrane has been coated with a polyvinyl alcohol (PVA) network, which is not soluble in alkaline electrolyte. The coating increases the hydrophilicity of the polypropylene. The diffusion coefficient of hydroxide ions (the species in the battery electrolyte enabling the electrochemical reactions of charge and discharge at the electrodes) measured experimentally is comparable to those of commercial separators. The coating developed in the project resists more than 2 weeks against ageing in alkaline electrolyte (see SEM picture B), which is not the case for the commercial separators tested. Furthermore, the coating process can be considered green since it does not involve organic solvent (aqueous solutions are employed) and is completed at room temperature. Finally, a successful scale-up of the membrane coating process has been achieved up to 250 cm², and the membranes obtained have been tested within 2.3 Ah batteries from Sunergy (scientific technical coordinator of LOLABAT). The best membrane allowed a cycle life of more than 1800 cycles, which is similar to the cyclability obtained with commercial membranes. Beyond proving the efficacy of the PVA coating in a real battery, these tests enabled to identify some sources of improvement, notably regarding the homogeneity of the coating. An even better cyclability is thus expected once the coating process will be fully optimized.