NiZn: towards cheap and environmentally friendly batteries (LCA and LCCA analysis)

The LOLABAT’s partners AITEC and OPTIMA conducted a comparative life cycle analysis (LCA) and life cycle cost analysis (LCCA) of Nickel-Zinc (NiZn) batteries, comparing them to Lead-Acid batteries, and Lithium-Ion batteries, their market competitors in energy storage applications. The environmental impacts were found to be intermediate between Lead-Acid and Lithium-Ion, and the costs were found very competitive!

The LCA considered the full life cycle of the batteries, with a focus on Cumulative Energy Demand (CED) and ReCiPe 2016 Midpoint and Endpoint impact assessment methods. The methodology is detailed in the third LOLABAT’s newletter.

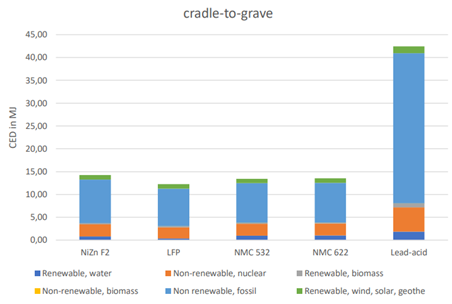

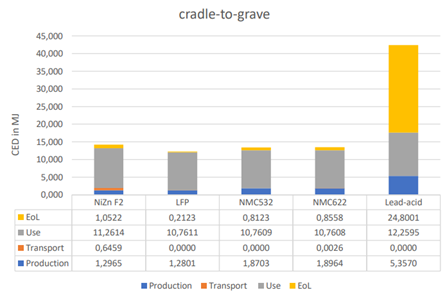

The NiZn battery's CED performance was found to be similar to Lithium-Ion batteries and better than Lead-Acid batteries. The use phase was the most impactful for NiZn and Lithium-Ion batteries due to energy demand from the grid, particularly non-renewable, fossil energy. Lead-Acid batteries showed the worst results, especially during the End-of-Life (EoL) phase, where pyrometallurgical treatment of scrap batteries caused significant environmental impact.

CED cradle-to-grave of all batteries with breakdown of impact categories (left) and of life cycle phases (right)

The environmental impacts of NiZn batteries determined with the ReCiPe 2016 Midpoint and Endpoint method, are between those of Lithium-Ion and Lead-Acid batteries, in line with the CED results. NiZn batteries have a similar environmental contribution as Lithium-Ion batteries. Lead-acid batteries show the worst performance due to lower energy density during the use phase and high pollution from pyrometallurgy treatment in the EoL. The comparison of endpoint assessment shows that among all the battery types the impact on human health and ecosystems was estimated to be significantly smaller than the damage on resources.

Midpoint and Endpoint cradle-to-grave analysis for all battery types (ReCiPe 2016 method)

In conclusion, the LCA study suggests reducing environmental impact of NiZn batteries through a greener electricity mix during battery use, improvement of the manufacture process and recycling, and improvement of the battery cell performance for better energy density and cycle life. Several aspects the LOLABAT’s partners are thoroughly working on!

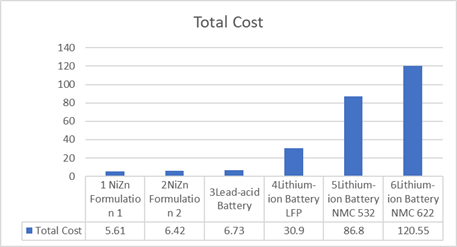

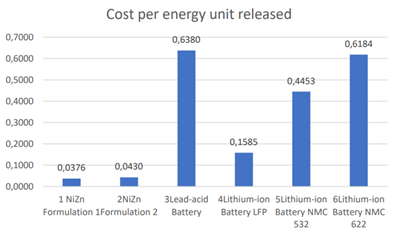

The life cycle cost analysis (LCCA) aimed to economically analyze two formulations of NiZn batteries developed within the LOLABAT project, and compare them to Lead-Acid batteries, and Lithium-Ion batteries. The cost is measured in euros per kilogram (€/kg) of battery mass and takes into account three key components: production cost, use scenario cost, and end-of-life (EoL) cost. When considering the total costs, NiZn Formulation 1 has the lowest total cost at €5.61/kg, followed closely by NiZn Formulation 2 at €6.42/kg and Lead-acid Battery at €6.73/kg. In contrast, the Lithium-Ion batteries have significantly higher total costs, reflecting their more complex production processes and EoL management requirements. When it comes to the cost of battery per kWh energy released, NiZn Formulation 1 and NiZn Formulation 2 exhibit the lowest cost per unit energy released. While the Lead-Acid battery has a relatively low cost per kilogram of battery, its significantly higher weight compared to other formulations results in a much higher cost per energy unit released. This study proves that NiZn batteries are an economically viable technology compared to other commonly used batteries.